The hotbed himself - from improvised materials. Simple greenhouse for seedlings: blueprints, photos, video

Growing vegetables in the countryside for manybecomes an exciting and fruitful occupation. Indeed, personally grown tomatoes or peppers are not only delicious, but also environmentally friendly. However, in our domestic latitudes the climatic conditions are such that it is impossible to simply throw seeds into the open ground and wait for a generous harvest. But to arrange the plants the necessary conditions simply - it is enough to build a hotbed with their own hands. Thus, it will be an ideal place for growing seedlings of different heat-loving crops, as well as vegetables and early greens to the table.

The greenhouse and the greenhouse - what's the difference?

According to many, a greenhouse and a greenhouse are conceptsalmost identical. True, when they talk about the greenhouse, they mean a more impressive structure. However, the main difference is that the greenhouse is heated using natural "batteries" - the sun, biofuel. This can be manure, which during the process of burning or burning creates a "greenhouse effect", resulting in plants receiving heat.

Regarding the value, the greenhouse for seedlingsmake small, because for the construction of a large structure of heat is not enough. Access to plants in the greenhouse provides hatches or hinged covers. Such a mini-greenhouse is a cheap and effective way to protect seedlings from spring colds.

A hotbed with his own hands from improvised materials

For the greenhouse equipment you can use the mostsimple handy materials that can be found in any household - a wooden and wire frame, plastic bottles, polyethylene pipes. Of the purchased materials you will need only a film (if not available at home). There are several types of simple greenhouses for seedlings, which by type of location are aboveground and in-depth.

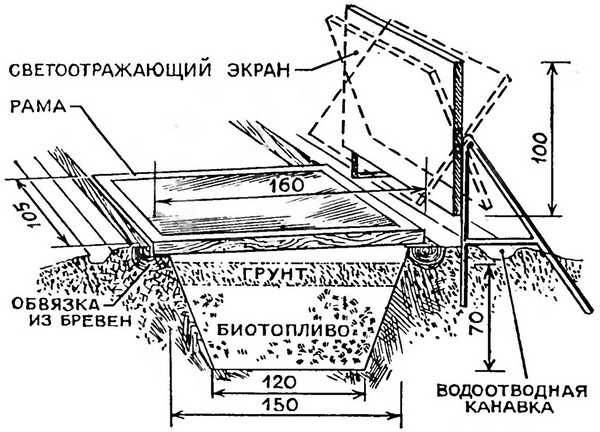

In the second variant, the structure is a trench, on top of which a bundle of logs is laid. A greenhouse of a deeper type retains heat better and requires less fuel.

The advantage of land greenhouses is theirmobility - can be rearranged from place to place. At the bottom of the structure is biofuel (manure), and the soil is on top. Over time, there is a decay of manure and soil shedding, so that periodically the raw material should be changed.

On the video - different options for home greenhouses for seedlings:

A hotbed with polycarbonate hands - at home (drawings, photos, videos)

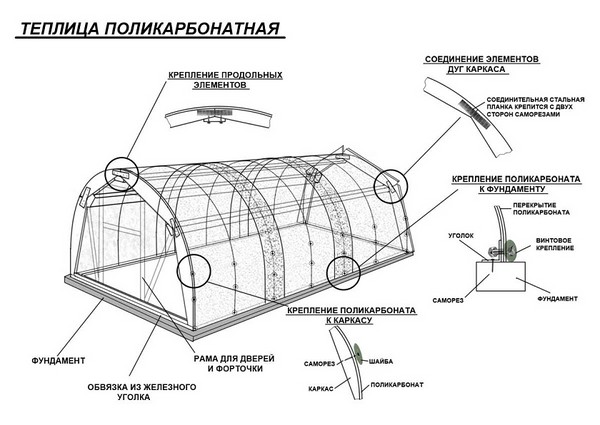

Polycarbonate is a modern material,providing protection from adverse weather conditions. Therefore, seedlings in the polycarbonate greenhouse will grow and develop well. In addition, the material is durable, transparent and pleasant in aesthetic terms. Despite the relative high cost, many for the equipment of greenhouses for seedlings prefer polycarbonate, and not affordable film.

For the frame it is better to choose a galvanized profileor a wooden beam. The first option is more reliable, which affects the cost of the design. A frame of the beam is not only easier to assemble, but also costs are cheaper. The disadvantage of wood is the fragility of its service. Therefore, this design requires periodic treatment with an antiseptic.

How to make a greenhouse in the country - a step-by-step guide:

Filling the foundation

For work we store:

with a wooden beam (cross section 12 x 12 cm)

ruberoid

linseed oil

galvanized self-tapping screws

roulette

hacksaw

shovel

Once a place is selected and cleared,It is necessary to equip the trench along the perimeter of the future structure. The width of the trench should exceed the width of the beam by 6 - 7 cm, and in depth go about 15 - 17 cm. For waterproofing we use roofing material, which we spread in a trench.

Wooden blocks are pretreated with linseed oil, and then placed deep into the trench - onto the layer of roofing material. We fall asleep with the ground and fasten the beams with screws.

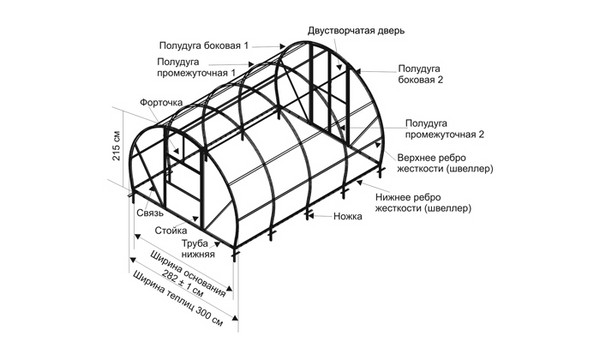

Frame made of wood

Materials for the device mini-greenhouse in the country:

cant timber section 5 x 7 cm

copper vitriol

metal fasteners - angled and T-shaped

Door hinges

self-tapping zinc-plated

roulette

wood hacksaw

screwdriver

We impregnate the beams with copper sulfate for the extensionlife of the structure. Screws the scaffold - it's the lower strap. We fix the side racks. Now cut the timber into pieces approximately 1.5 m. The spacing between two neighboring posts is about 0.6 m. We fix the side parts with metal fasteners on the lower bar.

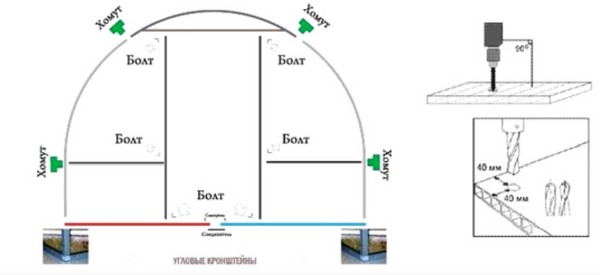

Next, fix the end racks and kakosinyframe, for which we take two timbers 0.5 - 0.6 m long. We fasten the end bars with the help of T-shaped fasteners and self-tapping screws. The drawing shows the location of these elements.

We make the upper frame of the frame - similarlylower. In this case, the front pillar will divide the beam into two halves. On the end stands we install the beam as an intermediate support. From above we place rafters, and then polycarbonate. It remains to make a door and attach a loop to it.

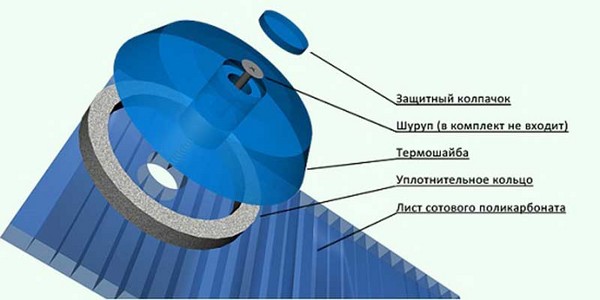

Installation of polycarbonate sheets

List of materials and tools:

polycarbonate honeycomb thickness 4 - 6 mm

sealing tape

perforated tape

manual circular saw

self-tapping roofing

drill

This is the final stage of the greenhouse device forseedlings. We process the ends, from one edge of which we glue the sealing tape in order to avoid penetration of liquid and dust into the polycarbonate honeycomb. On the other hand, the ends are closed with a perforated tape. Cut the sheets with a circular saw and carefully attach it to the frame with screws. Now you can remove the protective film from the material and everything - a homemade mini-greenhouse for seedlings is ready.

The best polycarbonate greenhouse with own hands. How to make a look here

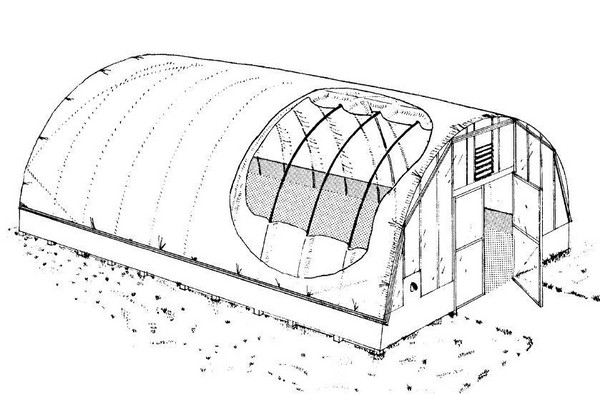

Greenhouse self-made of PVC pipes

PVC pipes are one of the simplest, affordable andinexpensive materials. So even the "beginner" summer resident will be able to cope with the construction. And our step-by-step guide will help to successfully cope with the work.

List of materials and tools:

PVC pipes - 6 pieces (diameter 1.3 cm, length 3 m)

boards - 2 pieces (5 x 15 x 240 cm) and 1 piece (5 x 15 x 180 cm)

Wooden beam - 1 piece (5 x 5 x 240 cm)

corners metal for fastening on screws - 4 pieces

clamps for pipes, with screws - up to 20 pieces

screws and nails, galvanized

a hammer

screwdriver or stapler

transparent film for shelter

The device of a hotbed with own hands from PVC pipes: a step-by-step description with a photo

Cut the board (5 x 15 x 180 cm) into two equalhalf - the end fences for our design were obtained. Then you need to dock these fences with two boards (5 x 15 x 240 cm). It turns out the box, which we put on a black plastic film - to protect the greenhouse from the weeds.

Mark the box under the pipes. At the edges we place two pipes, and the rest - through the same intervals. Now, each tube is carefully bent into an arc, fixed in a box and fixed with clamps.

From the remaining sixth pipe we make a crossbar, which we also fix with clips made of plastic.

We still have PVC pipe cuttings. They can be cut along and make "clips" for the film.

We turn the edges of the film under the bed - so our mini-greenhouse for seedlings looks more beautiful.

Cut out a piece of transparent film in sizegreenhouse and attach a stapler to our design. By the end of the film, you need to attach the wooden bar also with a stapler - this will make it easier to access the greenhouse.

Our homemade greenhouse for PVC seedlings is ready for "settling in".

The best greenhouse of window frames with their own hands. How to do, look here

A greenhouse for seedlings with their own hands is not so difficult to build. A little diligence and a minimal set of materials will bring remarkable fruits. Good construction and good harvest!