Plywood laying

To perform some repair work (for example, laying a parquet), you may need plywood laying. The country of the Soviets will tell you how to lay plywood.

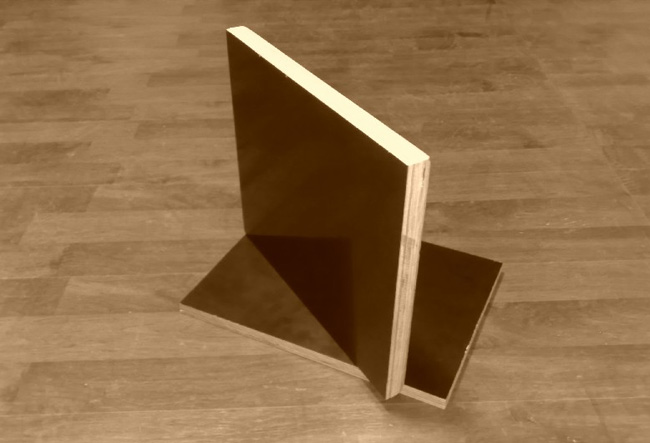

To perform some repair work (for example, laying a parquet), you may need plywood laying. The country of the Soviets will tell you how to lay plywood.Plywood sheet or plate is glued from several layers of veneer with the help of special substances. Depending on the mode of production there is peeled, planed and sawn plywood. The most commonly used is plywood. To obtain a sheet of plywood, veneer sheets are applied to the core of wood or other materials. Have homogeneous plywood the outer and inner layers are made of the same species of wood, combined - from different. There are also carpentry boards, their core is made of racks, so it is thicker than other layers.

Depending on the type of surface Isolate grinded (Ш2), unpolished (НШ) and laminated plywood. When classifying plywood, take into account and water resistance adhesive substances, highlighting its types:

- Plywood with limited moisture resistance (FB), used for non-essential parts.

- Plywood with medium moisture resistance (FS, FC, FBA), used for furniture production and interior finishing works.

- Moisture-proof plywood (PSF), used for outdoor works.

- Bakelized plywood (FBS), moisture and heat resistant, is used in the construction of ships and machines.

Plywood grades only four, they depend on the quality and external data of the veneer. Separately, the fifth grade is distinguished, the elite (E).

Why plywood is needed? Most often the plywood serves as the basis for the parquet floor. For these purposes, only a moisture resistant plywood is needed. Plywood Thickness depends on the planned thickness of the parquet floor. When the thickness of the parquet is up to 16 mm, the plywood is laid with a thickness of 10 mm, with a thickness of the parquet 16-20 mm plywood is laid 12 mm thick, and plywood thickness of 20-22 mm or a parquet of large sizes is plywood 15 mm thick.

The plywood is laid on the screed. Cement strainer compensates for unevenness and slope of the concrete floor. The better the screed is made - the more durable the parquet will be. The screed should not have cracks and voids. A good screed does not sag, does not swing, does not soften underfoot and does not break up into pieces. To check the strength of the screed, draw a nail on it with a nail with an intersection angle of 45 °. The tight screed does not crinkle at the intersections.

Plywood laying is carried out only on a dry screed. To check if the screed has dried, takea piece of polyethylene with a size of 1x1 m, lay on the screed and press it with a load. If after 2-3 days on the inside of the polyethylene there is no condensation - then the screed is dry, and plywood is possible.

Plywood laying begins with sawing sheets. The standard sheet of plywood has a size of 1525x1525mm. Each sheet must be sawn into four rectangular pieces. This will help ease tension and force on the plywood. Then plywood is laid on the floor in such a way that it does not touch the walls anywhere. The gap between sheets of plywood is 8-10 mm, and between the extreme sheets of plywood and walls - 15-20 mm.

Laying plywood is somewhat like brickwork: four sheets should not intersect at one point. When you have pushed the plywood sheets around the perimeter of the room, number them, sketch the layout and remove from the floor for a while. This is necessary in order to clean the screed surface from debris and dust, polish it. For these purposes it is best to use an industrial vacuum cleaner. Further, the surface of the cement screed is primed with a primer.

Then the actual plywood laying begins. For fixing plywood to the base, Self-tapping screws, glue and dowel-nails. To glue the plywood, you can usebitumen mastic (the cheapest option), rubber mastic or an alcohol based adhesive. Bitumen mastic is good for waterproofing, but it dries long and emits vapors. Rubber mastic dries faster and is better weathering. Adhesive on an alcohol basis is used in the event that it is not possible to use self-tapping screws.

On the base of each sheet of plywood, apply gluesmooth thin (no more than 2 mm) layer. Lay the sheets of plywood on the screed according to the sketched scheme and attach it with screws. The number of screws is about 30 pieces per square meter, and the length of each screw is 3 times the thickness of the plywood. Self-tapping screws need to be positioned on the principle of an envelope, pre-drilled holes for them with a screwdriver or drill. When plywood is finished, clean the surface of the plywood and dust and proceed to grinding.

Plywood grinding is produced by a CO-206 coding machineusing coarse-grained sandpaper (grain - 24-36). Align the plywood, check the floor plane with a long level. The permissible height difference is 2-3 mm for 3 m of the surface length.

Plywood laying has been completed successfully! Now you can start laying the parquet.