Window gratings

Window gratings in our time are very popular among residents of the first floors of multi-storey buildings, cottages. Metal window grilles allow you to feel safe and sleep peacefully.

Metal grilles on the windows serve to protect the premises from being hacked by robbers or other intruders. Window grilles are usually installed by residents of the first floors, since the windows are low enough from the surface of the earth and are one of the most vulnerable places of the home.

Metal window grilles are of several types. Fixed window grilles are considered the most reliable - they are mounted directly into the window opening and can be removed without a long and very noisy metal cutting procedure.

but stationary window grilles can not be installed on all windows in the room. After all, in case of fire, the owners of housing should bethe opportunity to leave the room through the window. To do this, at least one window in the room is equipped not with a stationary, but with a removable, sliding or swinging window grill.

Removable window grid looks like a stationary one, however it is attached towall on screwed bolts. If necessary, the bolts can be unscrewed, but this will take time, which in the event of a fire can simply not be.

Swing window grilles consist of one or two shutters and mortise orpadlock. Such window grilles are durable and reliable, and the key to the lock is in a secluded place (not accessible from outside) from the owners of the room. In case of danger, the owners can quickly open the lock of the window grilles.

Sliding window grilles extremely rarely used to protect windows in residential areaspremises. Such window grilles must be installed from the inside of the windows, besides, most of the sliding window grilles open the window opening only by 80%.

According to the rules of fire safety in premises withone entrance door though to one of windows in a premise it should be provided free access in case of ignition. Experts recommend that when equipping windows with window grilles, at least one grill should be made swinging.

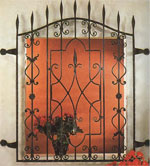

Window grilles can have different purposes. So, conditionally all the window grilles can be divided into decorative, decorative and security and security.

Decorative window grilles completely correspond to its name. Their task is only to formally block access to the windows, since their actual crack resistance is very small. Such window grilles are made of a chopped strip 1-4 mm thick. Between the rods the distance is quite large.

Security-decorative window grilles more resistant to burglary, but still not enoughreliably protect the premises from burglary. Manufacture of such lattices from the combined rolled metal of average section 10 mm. When installing, they are closed with external casing. Unfortunately, it is noiseless to crack the bars of the grid, if they are less than 16 mm in cross section, you can use ordinary wire cutters.

The most reliable security window grilles - to crack them, cybercriminals will need considerable time and power tools, which, of course, will attract attention with their noise.

According to the manufacturing method, window grilles can be forged and welded. Completely forged window grilles Is a very expensive pleasure, not available to everyone, but welded window grilles not so reliable.

Therefore, the most frequently used combined window grilles, in which there are forged and welded elements: forged elements of window grilles are made by the method of cold or hot forging, and then the construction is assembled by welding.

For the manufacture of forged window grilles, two main types of metal blanks are used: a square and a bar. Welded window grilles use a strip.

Window grilles are fastened in the window apertures in two main ways. With the first method of securing the latticeis installed "overlap": through the thickness of the wall, holes are drilled through the bolts, which will hold the window lattice. This method of installation is used mainly in houses made of timber.

In the second method of fixing in a layer of cementmortar or in the thickness of the concrete of the window aperture holes about 120 mm deep and about 16 mm in diameter are drilled. The holes are clogged with embedded pins, the free end of which is 20-30 mm from the surface of the opening. The window grid is welded to the protruding part of the embedded pins. This method is suitable for brick and concrete buildings.

Concerning decorative design of window grilles, then the choice of customers, as a rule,is not bad: you can choose the color of the lattice, its pattern. And if there are no samples in the samples submitted by the performer, then you can "collect" an individual pattern from several samples or create a completely unique pattern according to the customer's sketches.