Wet façade: warmed to winter

Not far off winter, and many private ownershouses are seriously thinking about the warming of their homes. You can warm the house both from inside and outside. Today we will talk about outdoor insulation, and more specifically - about technology "wet facade".

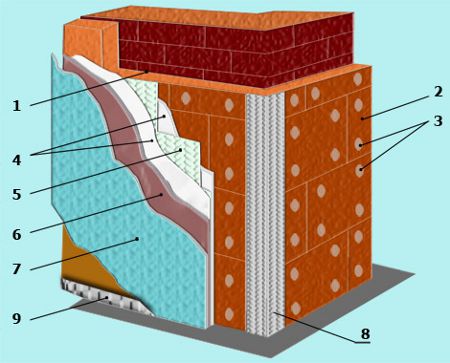

Not far off winter, and many private ownershouses are seriously thinking about the warming of their homes. You can warm the house both from inside and outside. Today we will talk about outdoor insulation, and more specifically - about technology "wet facade". Wet façade is a complex multi-layered structure. Conditionally it can be divided into three main layers: heat-insulating (usually made of expanded polystyrene or mineral wool), reinforced (mineral glue composition with alkali-resistant mesh) and decorative (primer, decorative plaster).

If you depict the wet facade schematically, in a section, then we can isolate such layers and elements:

priming (serves for better adhesion of the wall and insulation);

a plate made of heat-insulating material, glued with special glue;

dowels with bowl heads, with which the plate is additionally attached to the wall;

Stable glue and reinforcing mesh (adheres to the layer of the system and is the basis for subsequent outer layers);

reinforcing glass mesh, resistant to alkali;

primer, which serves as the basis for the decorative layer;

decorative facade plaster;

profile for the protection of corners;

socle profile, etc.

Let's take a closer look at the installation of each of the layers. Before installing the system, the "wet façade" prepare the wall, which you plan to insulate. It should be cleaned of dust, dirt, mold, plaque and excess solution, which held the bricks. The metal elements protruding from the wall must be cut off, the cracks should be closed. Then the wall is primed. After that, the socle profile is mounted. It must be built strictly horizontally.

The next stage of installation of the "wet facade" system is gluing of a heater. First you need to prepare a glue solutionaccording to packing instructions. Glue is applied to a sheet of insulation (mineral wool or polystyrene) according to the recommendations of the manufacturer of the insulation system that you use. Plates of insulation must be glued to the wall very tightly, so that the gaps between them were no more than 2-3 mm.

Drying of the heater requires at least 24hot weather and 36 hours - in cloudy, accurate figures, again, should be taken from the manufacturer's recommendations. Then the insulation is further strengthened with the help of facade dowels. For fastening to reinforced concrete, solidbricks and other dense substrates are used for driving dowels, and for fixing to foam concrete, hollow bricks and other porous substrates - screw dowels. It is very important to choose high-quality dowels with a low coefficient of thermal conductivity. The number of dowels is affected by several factors, but on average for a building up to 5 floors it takes 5-6 dowels per square meter of the wall.

Then the wet facade should be reinforced. Reinforcing layer Integrity of the whole system and in many respectsdetermines the durability of the wet facade. On a heater apply a glutinous solution, and then in it alkali-resistant reinforcing mesh from fiberglass is heated. The mesh is lapped, the width of the joints is at least 10 mm. Before reinforcement, you can apply a thin rough layer of plaster to the insulation, but you can not do this. The corners are reinforced by means of profile corners and other auxiliary elements. They must be alkali-resistant and compatible with other elements of the system.

The last layer performs two functions - protective (protectsa heater from harmful influences of an environment) and decorative (gives an aesthetic view to a building). First, the wall is primed, then a layer of polymer or mineral plaster is applied, and the finishing coat becomes the facade paint (usually water dispersive).

Wet façade is an effective thermal insulation system, but there are several "buts" in its use. At first, It is very important to choose a quality system. The "wet facade" system is not purchased in the formseparate components, but as a ready-made set in which all the details and elements are ideally suited to each other. You should choose a quality certified system suitable for local climatic conditions.

Secondly, Only qualified specialists should perform the work, amateur performance is unlikely to be successful, especially if you have no experience of construction work. And thirdly, Important for the successful installation are the weather conditions - the air temperature should be above + 5 ° C. Strong fluctuations in humidity prevent the process of gradual and uniform drying of solutions, this also needs to be taken into account.

The technology "wet facade" provides good heat and sound insulation, has a high level of energy saving (thus helping to save on heating). But to its installation in any case should not be neglected - miser pays twice.