Laying of concrete floors

Laying of concrete floors when building a building requires the study of the carriersthe capacity of the base and the consideration of the availability of groundwater. As a rule, these data can be found on maps of geological investigations on sites where construction is being carried out.

In addition, it should be remembered that Assessment of soil should be carried out by specialized research institutes or specialized firms. After processing of the received data it is given socalled a design solution for the construction of concrete floors. It usually takes into account such parameters as brand and thickness of concrete, reinforcement and thermal seams, recommended type of coating and much more.

Also, the laying of concrete floors involves calculation of expected mechanical, temperature and chemical loads. The object must be visited by a specialist in order to visually assess the condition of the site, take into account the evenness of the base, access roads and other nuances.

Usually, The laying of concrete floors begins with the leveling of the foundation. For this, optical,and laser devices. Before direct laying of concrete it is necessary to compact the soil. It is made in order to avoid cracks or subsidence of the base.

The next stage of surface preparation - sandbag laying, the thickness of which can vary from 50 centimeters to 1 meter. This layer must also be properly sealed.

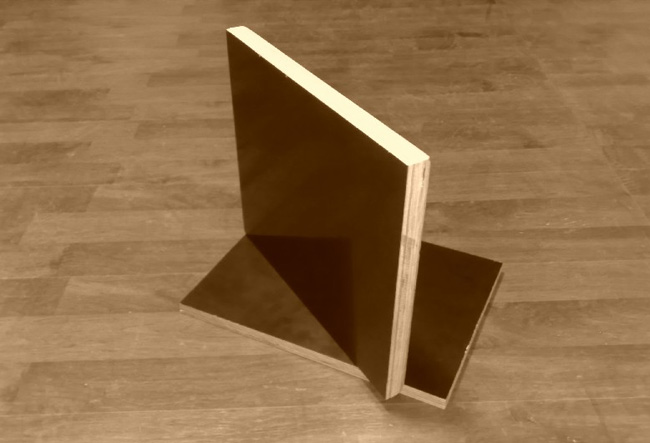

The construction of a concrete screed is performed by so-called "cards" - rectangles, the size of which depends on the area of the room itself. As a formwork is best to use wooden boards with a thickness of 2 centimeters. Next, you need to install the valve.

Laying of concrete floors implies concrete delivery on special concrete mixer cars. The material must be fed as close to the installation site as possible. If the floor is not filled on the first floor, it can be used concrete pump. When laying such a floor, concrete is necessaryto level. To do this, use a screed. The principle of its operation is quite simple: a screed rides on fresh concrete and stretches over its surface, under the influence of vibration concrete settles to the desired level.

After completion of the laying process, the concrete should be left on technological break, which can last from 3 to 7 hours. During this time the material has time to gain sufficient strength. Concrete should grasp so that the adult person, standing on it, left traces of a depth of 3-4 millimeters. It is in this period that you need to start deep grouting the surface. This procedure is performed using edge smoothing machines equipped with a freely rotating circle.

Followed by coarse grout using a machine with floating blades. Typically, this procedure is repeated twice to make the floor smoother. At the next stage, we are moving to the processing of seams, which can be of three types: insulating, shrinkage and structural. Seams are filled with polyurethane sealant. This approach eliminates the ingress of moisture, and also protects the seams from unwanted clogging.

As you could see, laying of concrete floors is a very laborious and complex process, which is best entrusted to specialistswho have the skills to use everythingnecessary construction equipment. In addition, the installation of such a floor has a large number of nuances. Also, there are technologies for laying concrete in the cold season.