Stacking of natural stone

Stacking of natural stone is not a very complex process, but requires the use of certain technical products, as well as compliance with construction standards and proper preparation of the material.

First of all you need to prepare the base for styling. It should be absolutely smooth and strong, nothave any cracks and dirt. The top layer of putty or plaster base should not crumble or flake. Check it is quite simple: just rub the palm of the surface on which you plan to lay the stone.

To test the strength of the base, take some hard sharp object and slide it over the surface. Pay special attention to the intersection points of the resulting lines. They can show possible peeling. Also, use the ruler-level to check the surface for irregularities. Be sure to remove old wallpaper and the remains of other decorative materials.

If you need to align the surface, it's best to use it putty on cement basis.

The laying of a natural stone is usually performed symmetrically with respect to the center of the wall or any other surface on which the installation is carried out. To do this, first on the wall is a line. Usually, Styling starts with large stones, and already having got close to corners of a premise, pass to use of more small.

If the height of the cladding does not have a clear limitation, Stacking should start from the bottom and use large stones for this. Further at an average height, a shallowmaterial, and finish the installation again using large stones. If the height is strictly limited, the stacking starts from above with large stones, gradually moving to smaller ones.

When laying stones on the floor, you should also stick to the symmetry, the axis of which should be drawn parallel to the long walls of the room. Close to the line should be placed large stonesand when approaching the walls, use small ones.

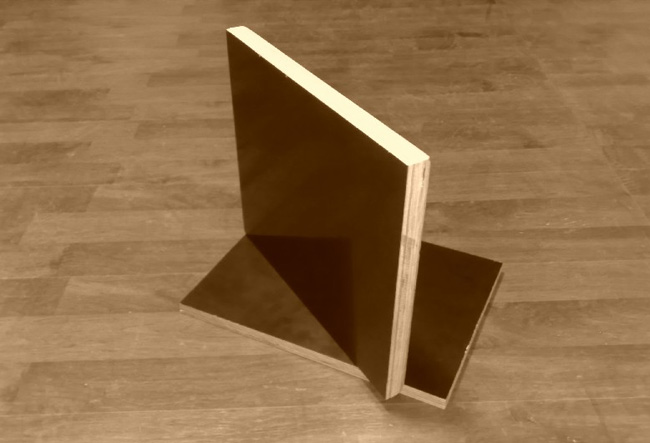

It will be necessary to resort to cutting stone in anycase, as it will have to revet the niches and ledges, which can be of a wide variety of shapes and sizes. In order to properly perform cutting, do not necessarily have a lot of experience. However, special stone processing tools. You can also use an ordinary grinder, in addition, it can be used to perform figured cutting of material.

The laying of natural stone, the thickness of which is less than 20 millimeters, is made for a special glutinous mixture. If the thickness of the material used is up to 50 millimeters, a cement-sand mortar. The temperature of the air during the installation should not exceed 34 degrees Celsius and at the same time be at least 5 degrees.

The solution must be applied with notched trowel, since in this way its distribution occurs evenly. It is also very important that the masonry has been completed before the mortar is seized. After installing all the stone slabs should be made polivku seams so-called cement-sand milk, which should consist of 30 percent of fine-grained sand and 70 percent of cement.

As you could see, laying a natural stonedoes not represent anything complicated, especially if you have previously dealt with the use of cement-sand mortar. However, if you are not sure that you will be able to do this yourself, we recommend that you seek help from specialists.