Dry floor screed

Dry floor screed This is a new technology that allowsquickly and efficiently make a new floor covering. The country of the Soviets will tell in more detail about this technology and how to make a dry screed of the sexes.

Dry floor screed This is a new technology that allowsquickly and efficiently make a new floor covering. The country of the Soviets will tell in more detail about this technology and how to make a dry screed of the sexes. It is not always possible to resort to the usual version of floor screeds. So, in old buildings during reconstruction orrepair of premises with wooden ceilings can not use a concrete screed, otherwise the load on the beams will increase. Also, a dry screed allows you to make repairs in an apartment in winter, when there are no conditions for performing cement screed. When installing heated wooden floors, you also have to resort to this method of dry screed. And make such a screed much faster than usual.

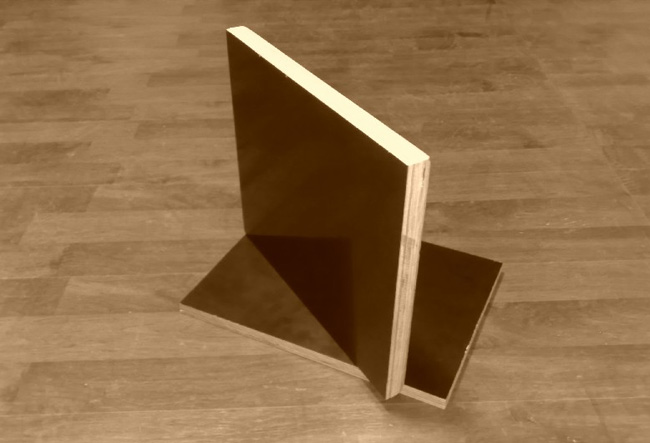

Dry, or team floor screed got its name only because it does not use water when it is mounted. After all, a dry floor screed is nothing more than aSpecial cement-fiber or gypsum-fiber boards, which are laid directly on the prepared surface. From below under the plates of dry screed there is a layer of special backfilling with thickness from 20 to 30 mm. This layer pre-leveles and prepares the floor for laying the dry screed.

The floor tie in the apartment is a responsible business, because with the slightest violation of technology coatingwill not last you very long. Entrust the laying of screed professionals. But if you feel yourself strong, then you can make a dry screed yourself. Tell you how to make a floor screed.

A dry coupler with your own hands will not give you big difficulties, if you know what materials and quantity you need. Contact the sales consultant in the store to help you calculate the number of required materials.

Dry floor screed in an apartment is not the hardest thing to doif you clearly know what you are doing and followtechnology of its packing. The fact is that the dry screed does not tolerate moisture. The moisture on the top slabs will also lead to bad consequences. Plates, which hit the water, disintegrate and swell.

To dry the screed of the floor is not in contact with moisture, on a cleaned and prepared for further work, the surface is laid around the perimeter of the moisture-proof material. It can even be a regular film that will not give moisture from the concrete floor of the house to get into the layer of the screed.

Across the perimeter of the room on the walls at the desired height from the floor level, draw a line to reach the dry mix for the screed. You can buy at a construction storea special prepared mixture. But you can also do with fine claydite or quartz sand. The main thing is that your mixture is dense enough and it can easily be leveled.

If you are not sure you can well level the screed mixture, you can resort to the help of lighthouses. It can even be ordinary gypsum plasterboard profiles. The furrows left by the profiles should be gently filled with the missing quantity of the filling mixture. On the perimeter of the room where you make a floor screed, you should also lay a sealing tape. It is best to use a 20 mm thick mineral wool strip.

Now you can start laying the dry floor screeds. Carefully put all the sheets on the floor, tightly fitting them to each other. To give them strength, the sheets are twisted or glued together. And using a putty mask the seams, so they do not interfere in the future.

Dry floor screed - this is a very economical option. With the correct selection of sheets you can notjust make the floor screed very quickly, but also save money. So, in order not to lose with the size of sheets for screed, we advise buying small plates, because they weigh a relatively little - up to 15 kg. Also with a dry screed it is much easier to work than with traditional materials.