How to make a floor screed with your own hands

If you decide to lay a laminate floor on the floor, parquetor you want to put ceramic tiles on the floor, then you already know that only a flat surface is suitable for this. To smooth the surface of the floor, it is customary to make a screed. You can trust the device of the coupler to a professional and be calm for the result and the money spent. And you can, with a sufficient supply of time and patience, save a significant amount and make a screed with your own hands.

Screws serve primarily for levelingfloor, but they also have to withstand the load on the floor. There are several types of screeds. The main ones are cement-sand and concrete. In addition, dry (gypsum), magnesite, anhydride, mosaic, epoxy and asphalt screeds are also popular. The latest novelty - self-leveling floors, made on the basis of ready mixtures of cement, sand, plasticizers and aggregates.

Screed can be arranged directly on the overlap. Such a screed is called baseless or rigid. If the screed is arranged on a layer of heat, hydro- or sound insulation, it is called "Floating" or separate.

At the stage of preparation for screed, it is necessary to clean the surface overlapping of dust and debris, primed, and allfill the gap with a thick solution. It is necessary to protect all walls and partitions in the room from absorbing moisture. To do this, you can paste a strip of roofing paper on the lower edges of the walls so that the upper edge of this strip protrudes 15 cm above the level of the future screed.

Before starting work you need to make a markup to determine the level of screed. If you have a laser level, then the markup can be done with it. And you can apply another method. It is necessary to make a mark on the wall at a convenient height for you and use the usual level (water level) to gradually move this mark around the perimeter of the room so that on each wall there are 2-3 marks. By connecting all the marks with straight lines using a ruler (meter), you will get a zero level, from which you should repulse at work. Make several measurements from the level of marks to the surface of the overlap. With their help you will learn the maximum and minimum distance between the marks and the surface.

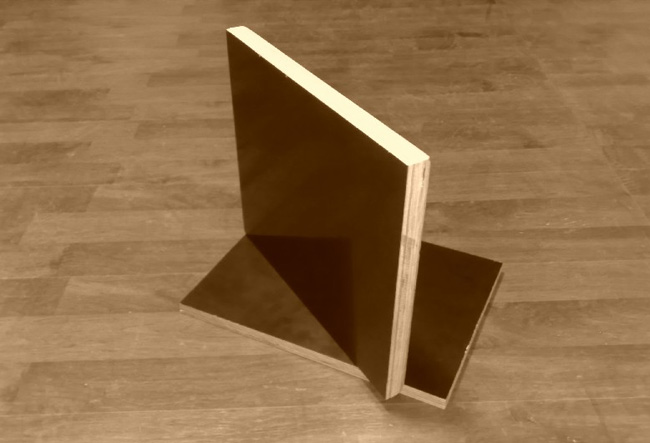

Read the filling of the screed is recommended from the installation "Lighthouses". As a "beacon" can act boards or,that more modern, metal profiles, which are attached to the base with screws or with the help of a thick solution. "Lighthouses" set at the desired level, at a distance of not more than 1-1.5 m from each other.

Home screed solution can be prepared in a basin or bucket using an electric drill with a specialnozzle-mixer. Consistency of the finished solution should be like a thick dough. Do not prepare the solution in advance, because it is fit to use no more than 1.5 hours.

To begin the device of a coupler professionals recommend from the highest point. The applied solution must be leveled and rolled with a needle roller so that the solution lies more evenly, and there are no air gaps. Align the solution to the level. Lean the level on two adjacent "beacons" and level the surface until it becomes even.

Remember that the optimum temperature for workabove the screed is approximately 20 ° C. In the room at the time of operation there should be no drafts. It is advisable to finish the screed of one room or the same level (when the screed is made in the same room for different floor coverings) in one day.

If the coupler is made in a large room, then you need to take care of special expansion joints, which are small gapsbetween screed arrays. Strain joints are filled after the main screed. The finished screed can crack if you do not moisten it a couple of times with water. On the second or third day after laying the screed, you need to remove the beacons and fill the voids in their place with a solution.

Do not start laying the flooring more than 30 days after the screed. It is just so much time you need cement in order to gain sufficient strength.